A summary of the iModBatt project results was published in the EGVI website in November 2020. EGVI, the European Green Vehicles Initiative is a contractual Public Private Partnership (cPPP) dedicated to delivering green vehicles and mobility system solutions of the future which match the major societal, environmental and economic challenges. CIDETEC is part of the EGVI association (EGVIA), engaged with the European Commission into the EGVI cPPP in order to represent the private side of the partnership. EGVIA gathers representatives from the automotive, smart systems and smart grid industries as well as research centres and universities. The association is continuously growing, testifying the attractiveness of the EGVI cPPP in the road transport community.

The summary of the achieved results by now can be summarized as follows.

- Increase in BP energy density

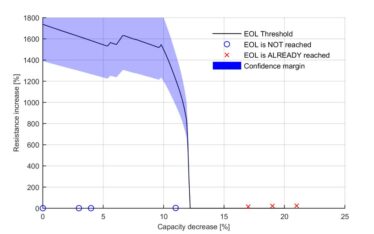

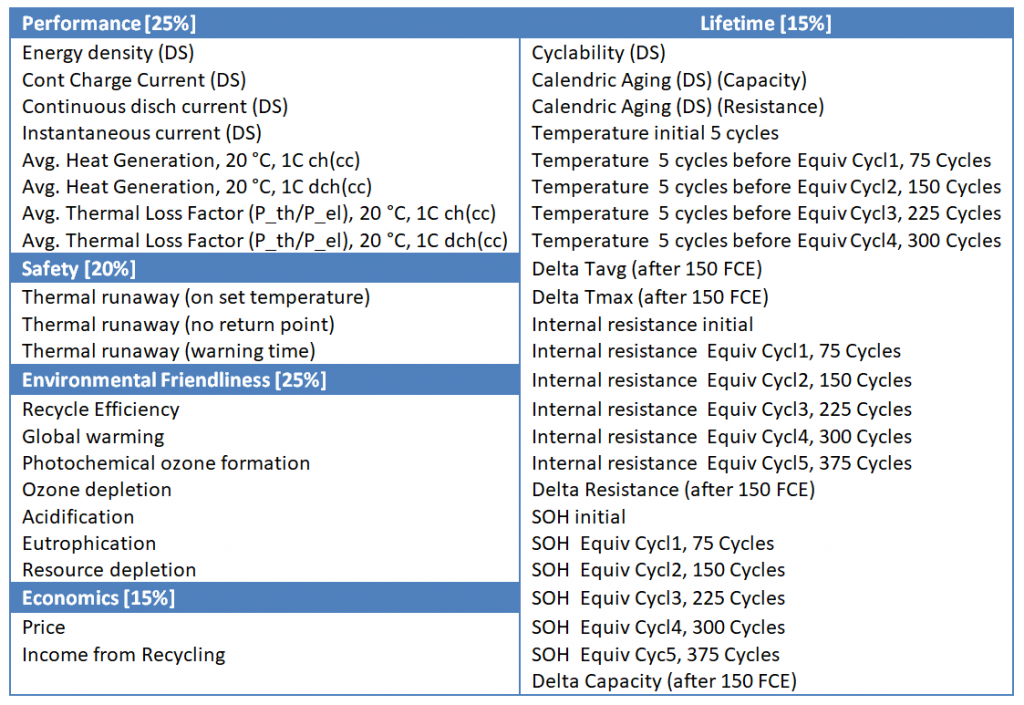

- Selection of Li-ion commercial high energy density cells for the defined application after electrical, thermal and ageing test

- Final cell selection according to several parameters with specific weights according to iModBatt project goals.

Table 1: Cell selection parameters including importance [%] according to iModBatt goals

- BP effective packaging with selected cell to fit to the available volume in the cars while keeping modularity concept and energy density optimization:

- Renault: 13 modules in 7S28P à 2 strings 13 modules in 7S14P

- GO: 13 modules in 7S14P

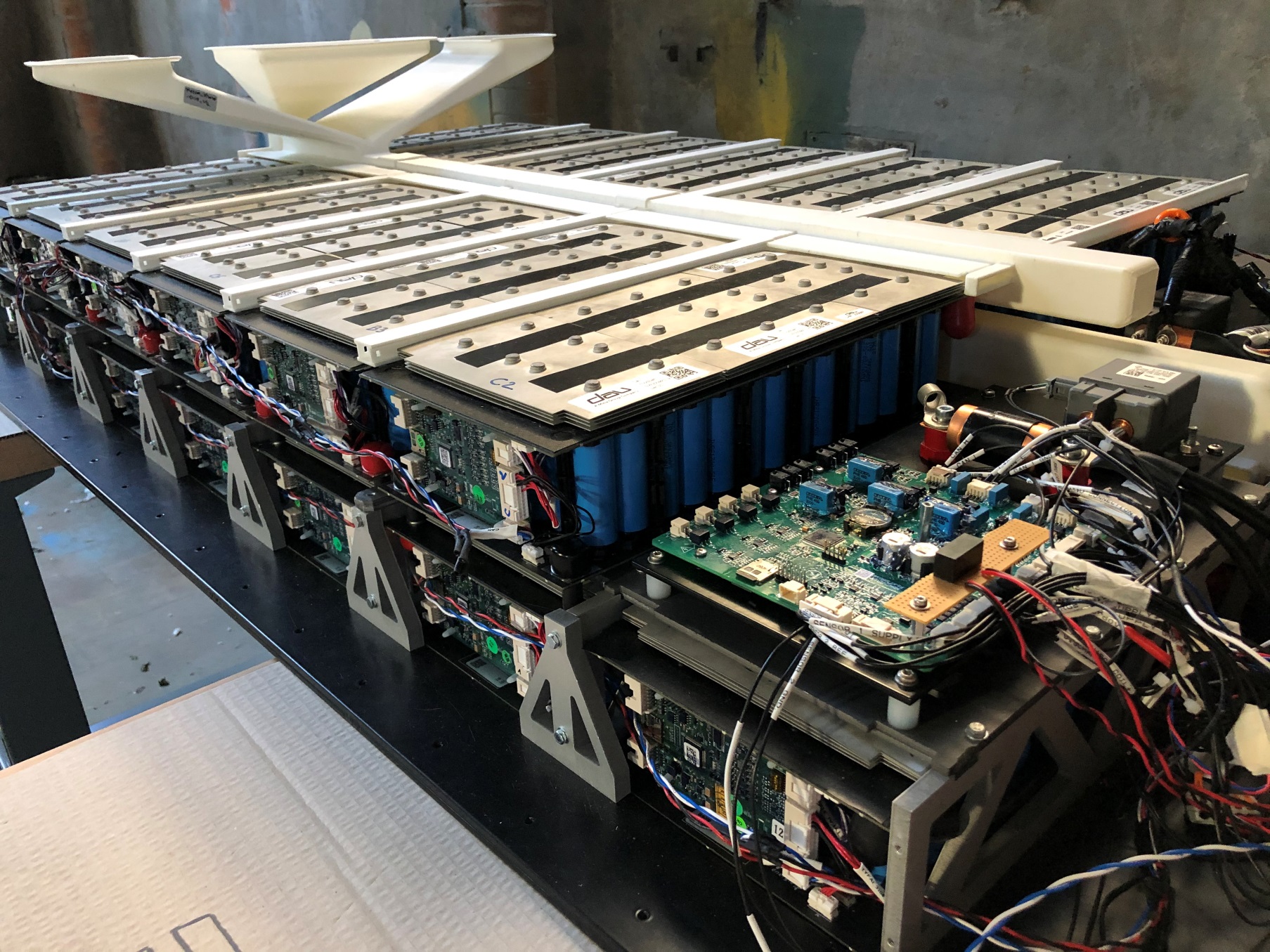

- Design of a lightweight modular BP structure. Reduction of wiring due to the use of aluminum or copper connection layers on PCBs. Use of low volume thin materials and thermal interface materials to improve thermal conductivity. Figure 1 shows the first REN BP during a check-up test and this video explains the whole iModBatt (dis)assembly concept.

Figure 1: Assembly of the REN BP (during check-up test connected to external devices)

Figure 1: Assembly of the REN BP (during check-up test connected to external devices)

- Reduction of the BP integration cost

- BP module automated assembly.

- Cell flexibility per module decreases cell availability derived costs.

- BP modularity impacts on production flexibility.

- The increase in the time value of the BP due to the expected life extension reduces the BP production cost.

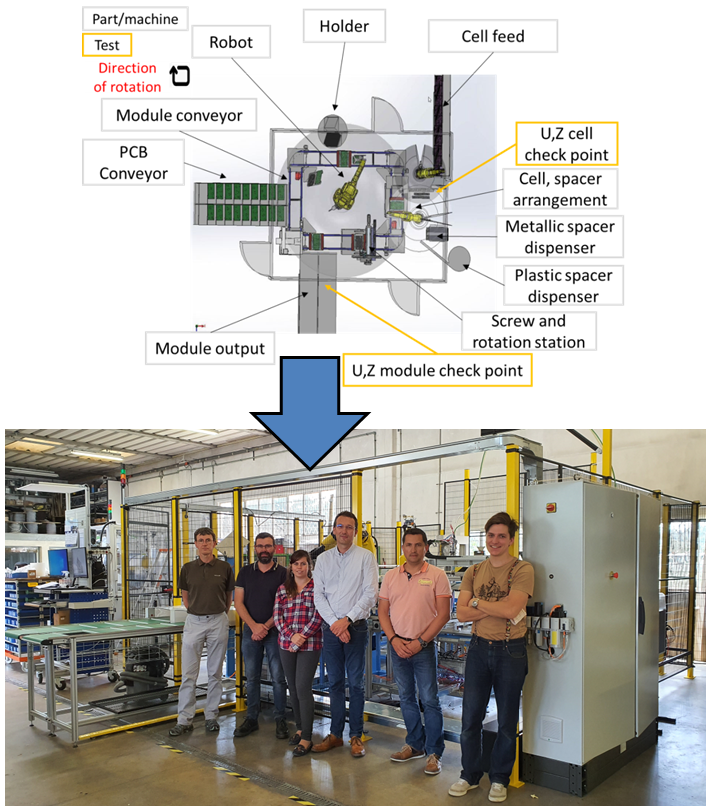

The proposed solution for the BP module automated assembly is presented in this video and the sketch-to-real life shift has been already fulfilled as indicated in Figure 2.

Figure 2: From conceptual sketch to real set-up of automated battery module assembly Unit.

Figure 2: From conceptual sketch to real set-up of automated battery module assembly Unit.

- Enhance the value of European SMEs and large industries

- TYVA Energie (SME, France) is the leader of WP3 and WP5, focused on the electrical design and the module automated assembly accomplishment, respectively.

- Freemens (SME, France) lead the BMS customization and power electronics definition.

- MIBA (IND, Austria) is the leader of WP4, focused on the thermal design and more specifically, MIBA design & manufacture the main thermal HW (cooling fins-pipes device).

- Rescoll (SME, France) is the leader of WP7, focused on the modularity and flexibility validation for automotive application, second life and recycling.

- Accurec (SME, Germany) lead the recyclability analysis of the proposed BP modular concept.

- Eco-design recommendations and defining a smart recycling methodology

- A preliminary Life Cycle Assessment was defined and now it is being updated till the end of the project in March 2021.

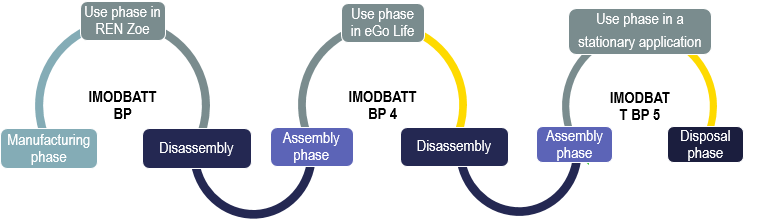

Figure 3: BP extended life scenario for LCA calculation

Figure 3: BP extended life scenario for LCA calculation

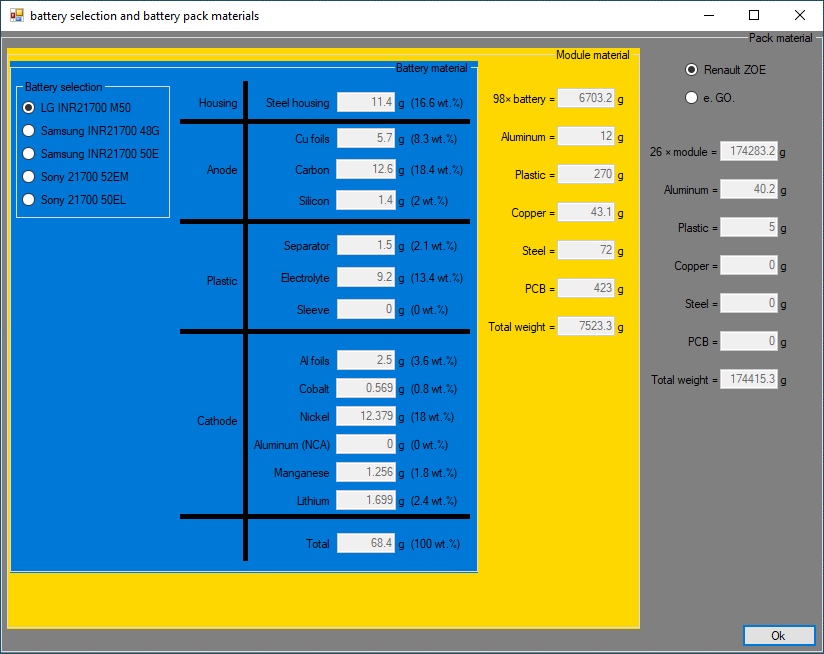

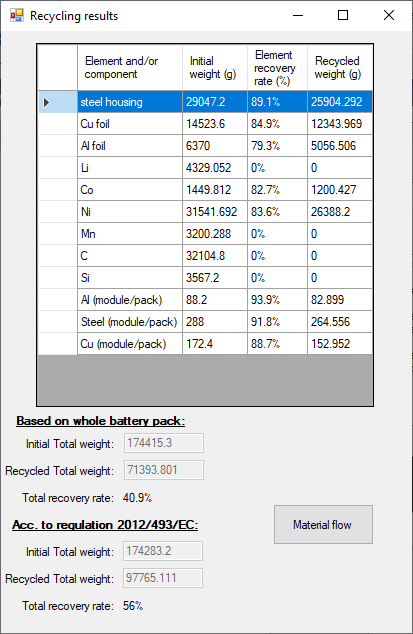

- Based on the achieved data on the tested cells and the bill of material of the iModBatt two BP concepts, a SW has been created to obtain the recyclability degree. The software allows the user defining the input material for recycling and selecting the recycling process from 4 possible routes and dismantling level (until module level, cell level or do not dismantle). The recycling result summarizes all available elements in the selected input BP and their overall recovery rate over the selected recycling process.

|

|

- Second life and/or reuse of BP

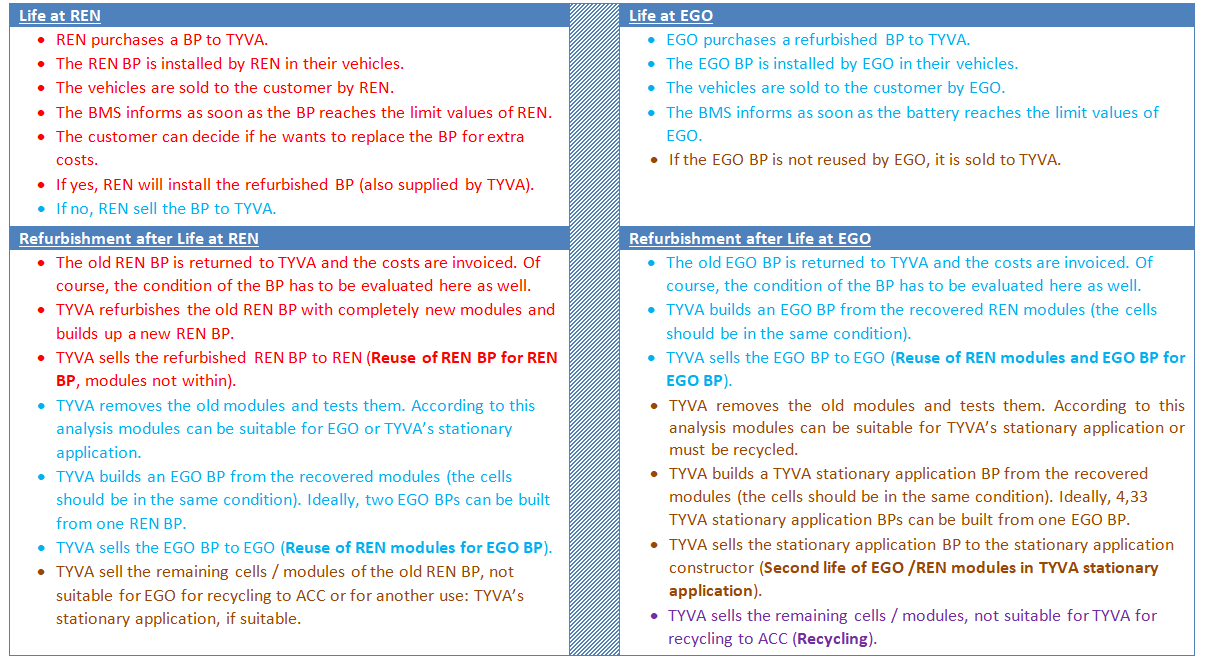

- A potential reuse and second life scenario has been described between the REN vehicle, EGO vehicle and the TYVA power pack applications. The Consortium is now finishing this analysis to define how/when a BP should be shifted from one scenario to the next one:

Table 2: BP reuse and second life scenarios according to iModBatt (preliminary)

Next steps in iModBatt till the end of the project in March 2021

- BPs will be tested at lab level and integrated in the REN vehicle.

- The automated module assembly unit will be used to build a battery module as proof of concept.

- The LCA will be updated according to the final data.

- The BP reuse and second life use scenarios will be finished.

Figure 4: Input material definition for recycling calculation

Figure 4: Input material definition for recycling calculation Figure 5: Recycling result of selected

Figure 5: Recycling result of selected